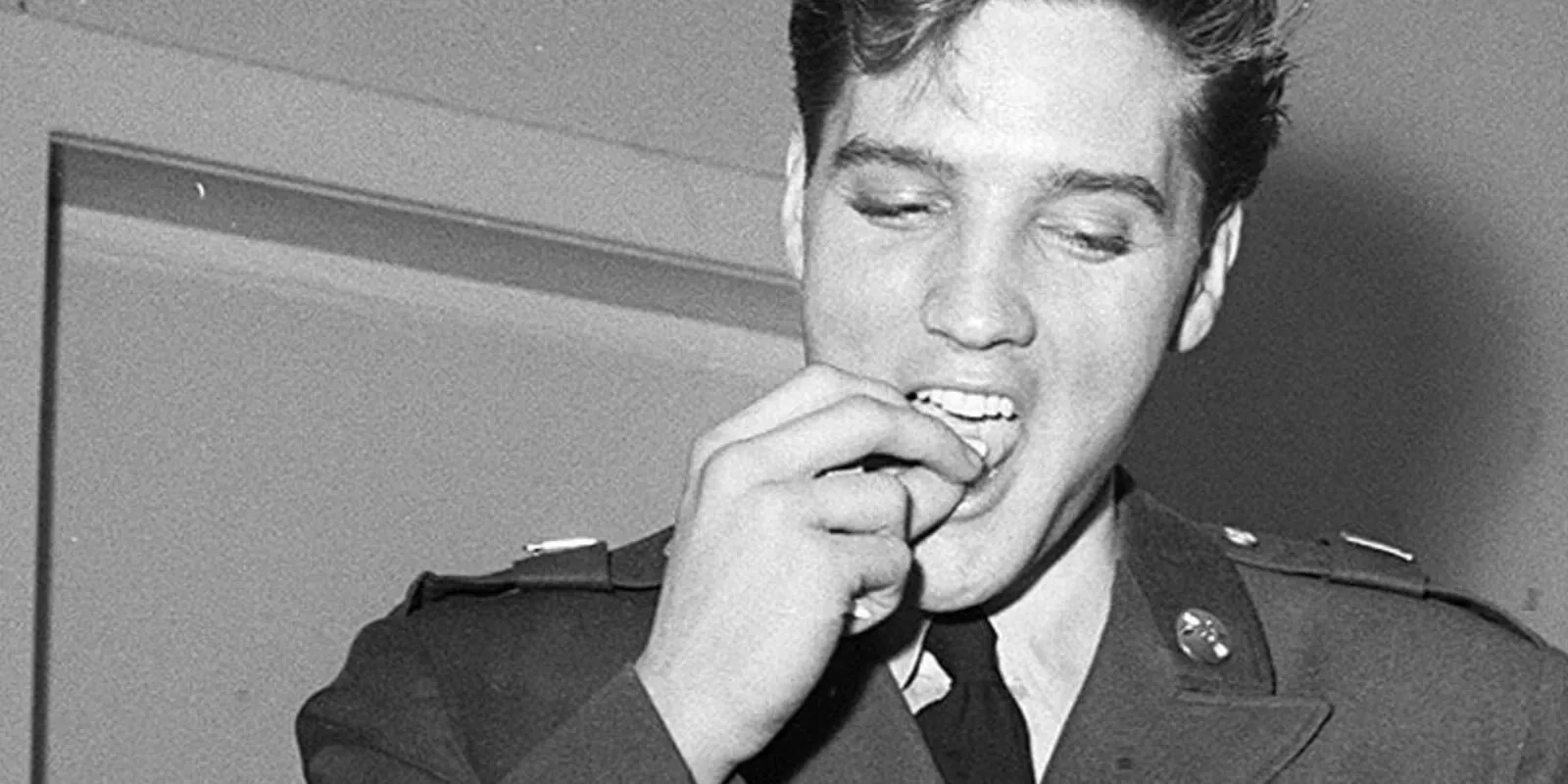

Elvis Presley’s Favorite Birthday Cake: What Was the Sweet Treat He Asked For on His Special Day and All Year Long?

Elvis Presley had many sweet treats. However, his favorite was a cake he regularly requested whenever he wanted a slice for his birthday and all year long.

Elvis Presley’s favorite birthday cake was sweet, salty, and delicious

Legend has it that one of Elvis Presley’s favorite birthday cakes was a traditional southern pineapple pecan delight with a vanilla cake base. He reportedly loved this dessert so much that he often asked for it for birthdays and other occasions.

Reportedly, this cake was a specialty of one of Elvis’ grandmothers. Other stories have the cake originating from the recipe book of Graceland’s longtime cook, Mary Jenkins. The dessert was perfect for celebrating birthdays, holidays, or any other reason a dessert was in order.

The cake uses a boxed cake mix, with cream cheese, pineapple, and pecan topping. It comprises all the favorite tastes of Elvis’ childhood into one delicious bite.

It is an easy cake to make. The glaze is just a can of crushed pineapple boiled on the stovetop with a cup of sugar. The icing includes cream cheese and confectioner sugar, heated until all are combined to form a thick icing. The cake is then topped with the icing and crushed pecans.

Get the full recipe on Food.com.

What other types of sweet treats were always on hand at Graceland?

Elvis Presley had a list of favorite foods that needed to be kept on hand at all times in the Graceland refrigerator. However, Elvis requested one item that should always be at the ready in case he decided to eat it.

According to Elvis’ longtime cook Mary Jenkins, that food was banana pudding. The dessert was made fresh each evening.

Per The New York Times, Jenkins said “The only thing in life he got any enjoyment out of was eating. And he liked his food real rich.”

The Times said that Jenkins cooked items such as cheeseburgers, chicken-fried steaks, hamburger steaks, caramel cakes, and huge bowls of banana pudding. He also loved sweet and salty peanut butter and banana sandwiches, which Jenkins said she perfected alongside his father, Vernon Presley.

Elvis’ father suggested toasting the bread before putting it in the skillet. Jenkins said, “It’d be just floating in butter. ‘You’d turn it and turn it and turn it until all the butter was soaked up; that’s when he liked it.”

Elvis Presley’s cook perfected the King of Rock and Roll’s meals

Mary Jenkins claimed that Elvis liked everything he ate filled with flavor. He wasn’t a fan of bland foods.

“For breakfast, he’d have homemade biscuits fried in butter, sausage patties, four scrambled eggs, and sometimes fried bacon,” she said to The New York Times. “I’d bring the tray up to his room, he’d say, ‘This is good, Mary.’ He’d have butter running down his arms.”

“It’s not true that Elvis liked burnt bacon sandwiches,” she added. “He liked his bacon very crisp.”

According to the book The Life and Cuisine of Elvis Presley, Graceland’s refrigerator had to be stocked with certain foods. Many of these snacks, meals, or desserts had to be made fresh daily in case Elvis wanted them immediately.

The items in Elvis’ refrigerator included fresh, lean, unfrozen ground meat, a case of Pepsi Cola, and brown-and-serve rolls. Cans of biscuits, hamburger buns, pickles, potatoes, and onions were also included.

Fresh fruit, yogurt, sauerkraut, frankfurters, milk, cream, and bacon were also at the ready. Mustard, peanut butter, hand-squeezed orange juice, ingredients for meatloaf, and ice cream rounded out the food that Elvis’ cooks always had to have on hand to serve the King of Rock and Roll when he requested them.

Mary Jenkins worked for Elvis Presley in 1977 up until his death on Aug. 16.