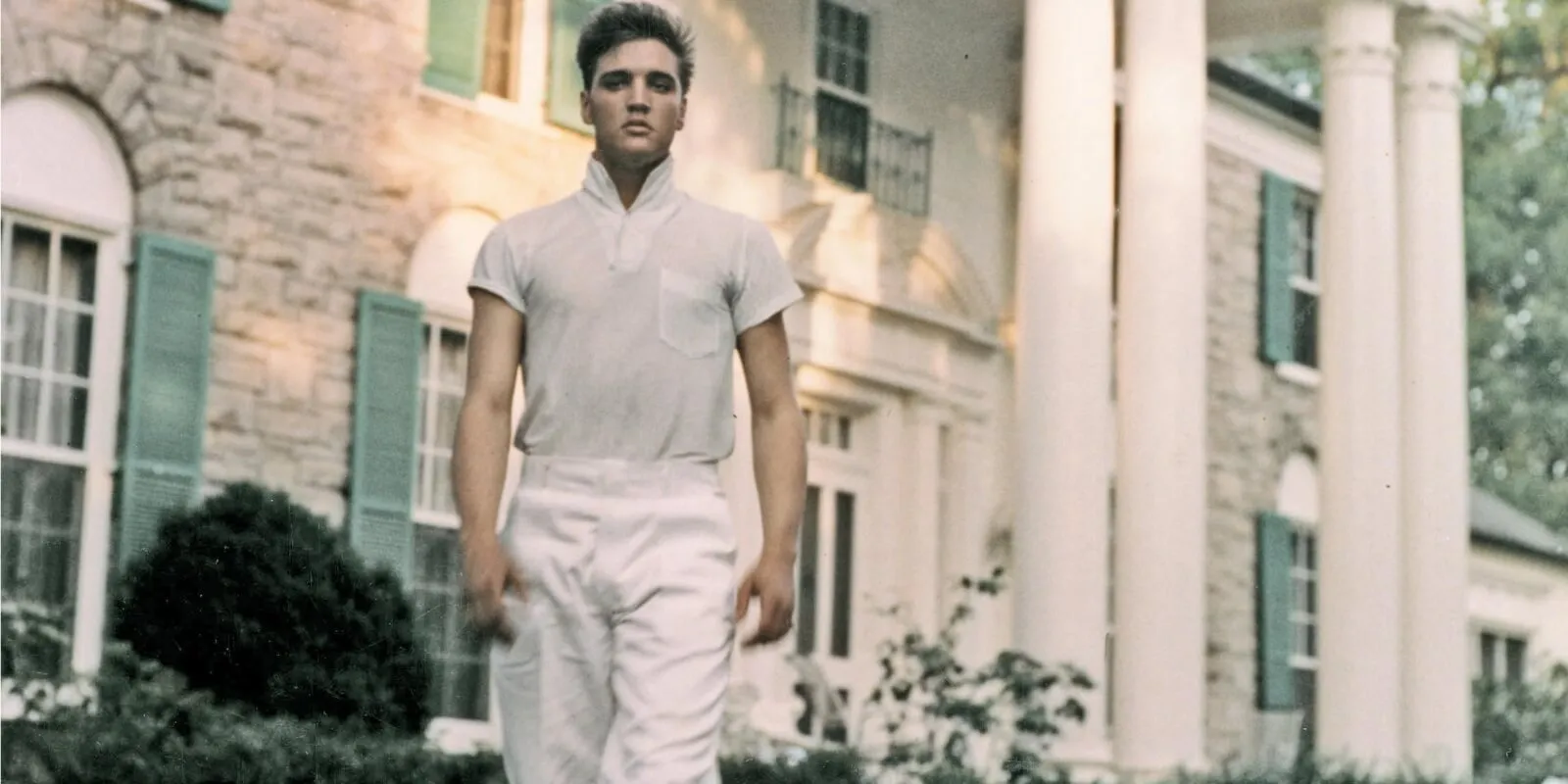

Elvis Presley’s 90th Birthday: How Will Graceland Celebrate?

On Jan. 8, 2025, Elvis Presley would have turned 90 years old. To celebrate the milestone birthday, Graceland will throw a party for fans that includes all the elements of a great celebration: music, celebrities, cake, and of course, at the center of it all, the King of Rock and Roll.

Graceland celebrates Elvis Presley’s 90th birthday with 4 days of events

According to Graceland’s official website, the iconic Memphis estate will celebrate Elvis Presley’s 90th birthday with four days of exciting events.

The home will welcome a thrilling lineup of performers and guests, all connected to the King of Rock and Roll. In 2025, Graceland celebrates with the Oak Ridge Boys’ Richard Sterban (also a backup singer for Elvis), The Imperial’s backup singer Terry Blackwood, and member of the Sweet Inspirations Estelle Brown. Also in attendance will be martial artist Bill “Superfoot” Wallace, songwriter Terry Mike Jeffrey, “Ultimate Elvis” performer Dean Z, tribute artist Pat Dunn, Sirius XM radio personality Argo, and broadcaster Tom Brown.

Graceland hosts a free birthday event on the home’s lawn, featuring a huge birthday cake paying tribute to the entertainer. During the event, Memphis and Shelby County officials will read a proclamation of Elvis Presley Day. Subsequently, fans from around the world can participate in this exciting moment by streaming the ceremony online for free at Graceland’s Vimeo page.

Visitors to the home will also continue to enjoy its festive holiday decorations. Elvis kept his Christmas tree and other items up through New Year’s Eve to his birthday and Graceland continues that tradition.

Graceland honors Elvis’ 90th birthday with a new exhibit

A new exhibit named “90 for 90” debuts at Elvis Presley’s home on his birthday, Jan. 8, 2025. It will remain an installation at Elvis Presley’s Memphis complex, across the street from the historic home, for one year.

Graceland’s official website states this new series features 90 curated artifacts. Each item spotlights key moments in Elvis’s personal and professional life.

Some of the artifacts on display in the new exhibit include Elvis’ sketchbook and a pair of checkered boots belonging to the King of Rock and Roll. Also included are a 1954 Blackwood Brothers Quartet performance card and a realtor card for the home Elvis shared with parents Vernon and Gladys Presley at 1034 Audubon Drive in Memphis, Tennessee.

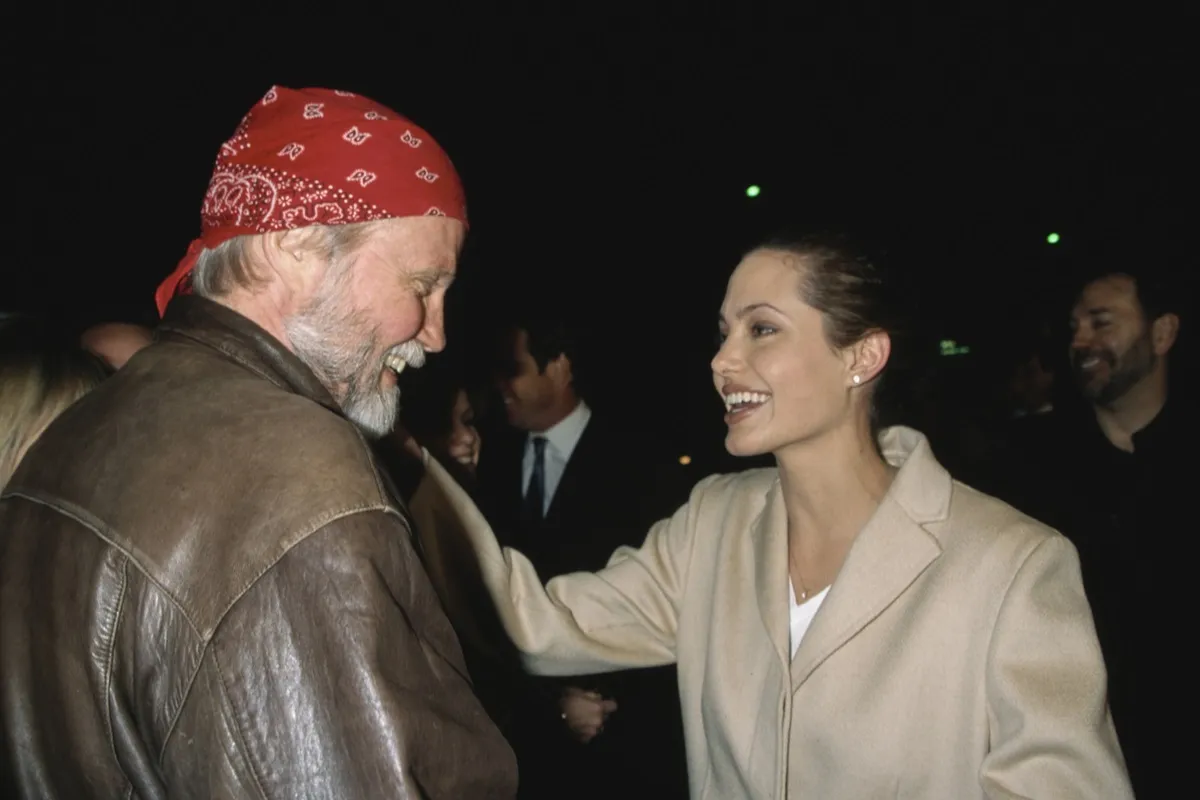

Lisa Marie Presley attended Elvis Presley’s Graceland birthday celebrations

Graceland’s birthday celebrations were always important to Lisa Marie Presley. The estate was Lisa Marie Presley’s home, even after she moved to the West Coast with her mother Prisiclla Presley upon her parents’ 1973 divorce. Lisa Marie regularly spent holidays and school vacations with her father in Memphis, Tennessee, and continued to visit the home after Elvis’s death in 1977.

Lisa also attended many of the yearly celebrations honoring her late father. However, just days after attending his 88th birthday celebration in January 2023, she died.

During her last Graceland birthday event, Lisa Marie told the crowd, as reported by The Commercial Appeal, “Thank you. It’s been a while. I missed you. I keep saying you’re the only people that can bring me out of my house. I’m not kidding.”

“That’s why I’m here. Today, [Elvis] would’ve been 88 years old, it’s hard to believe. I think that he’d be proud,” Lisa Marie continued.

“It’s just so moving how every year you come from all over the world. It’s moving to me and my family. So thank you.”

Lisa Marie died four days later. It was determined that her passing was a result of cardiac arrest caused by a small bowel obstruction.

Elvis Presley’s birthday celebration at Graceland’s begins Jan. 8, 2025, and runs through Jan 11. The home will offer free morning walk-up visits to Meditation Garden from 7:30 am to 8:30 a.m. from Jan. 8-11. There will be evening walk-up hours on Jan. 7 through 10 and Jan. 12 from 6 p.m. to 7:30 p.m.