15 Pro Tips To Handle Emergency Generator On Ships

On ships, there’re a separate set of systems provided both on deck and engine room for emergency situations. Some of the most important emergency machinery and systems on board ships are – Emergency compressor, Emergency bilge suction, Emergency fire pump, Lifeboat, and Emergency generator.

As per the SOLAS requirements, all emergency equipment/systems must be tested frequently (general practice on a ship- weekly) to ensure they run smoothly when really needed, especially in an emergency situation.

Out of the all the systems, the emergency generator is one of the most frequently used machinery as a blackout situation can occur anytime on a ship.

Therefore, it is very important not only for the engineer officer but also for the deck officer/crew to know the ways of starting and testing the emergency generator, as per the regulations laid down under SOLAS.

Important requirements for the prime mover of the emergency generator are:

- The emergency electrical power providing generator shall be driven by a suitable prime mover having independent auxiliary systems, which may consist of fuel, ventilation, lubrication, cooling etc.

- The fuel used in the emergency generator prime mover must have a flash point of > 43° C

- The prime mover of the emergency generator shall be started automatically once the main source of electrical power supply fails

- If the emergency generator does not start or does not take the load of the emergency switchboard connections, an indication shall be given in the engine room or at a manned control station

Related Read: How The Power Requirement Of A Ship Is Estimated?

Apart from complying with the SOLAS Ch II Reg 43, the important job of ship’s engineers is to maintain the emergency generator in top notch condition.

Following are the important points that should be remembered when handling emergency generator:

1. Anti-freezing compounds are added to the emergency generators to ensure it will start even at very low temperatures (-ve temperature). If using fully formulated anti-freeze compound, mix it with good quality water in a ratio of 1:1 or as stated by the manufacturer. If the fully formulated antifreeze compound concentration is kept higher than required, the cooling system may silica gel formation issue.

Related Read: What to Do When the Ship is Moving towards Sub Zero Temperature Area?

2. When mixing anti-freeze solution to the system, avoid pouring it alone in the radiator. It should always be mixed in the prescribed ratio with water before pouring into the cooling water system of the generator. This is because the potential of the ant-freeze liquid to remove heat is not as good as that of water and putting the anti-freeze compound alone in the cooling system may contribute to overheated condition before the liquids are completely mixed together.

3. Coolant is used in the engine cooling water system to control the overheating of the generator. They are added mixing with water. Never add coolant mixture at a low temperature to a hot engine. This may lead to damage to the engine casting. Always stop the engine and let it cool down before adding the coolant mixture.

Related Read: 8 Important Points To Note For Maintenance Of Emergency Generators On Ship

4. When adding the coolant mixture after a major overhaul or draining the cooling system, ensure to open the engine and aftercooler vent while filling the coolant to the system to allow air to escape and avoiding airlock

5. It is not a good practice to test the cooling water used in the emergency generator after a long interval of time. Ensure to test the cooling water quality every week and maintain it at a pH of 8 – 10.5 to avoid excessive scaling problem (if calcium and magnesium levels are more) or corrosion problem (if chloride and sulphate levels are more)

Related Read: 10 Important Tests for Major Overhauling of Ship’s Generator

6. Unlike auxiliary engine generator, the emergency generator should not be idled for a long period. Long idle timing (more than 10 minutes) will affect the fuel burning as combustion chamber temperature is very low. This will cause carbon clogging of the injector holes and sticking of the valve. The best idle time is considered to be 3-5 minutes for the emergency generator.

7. If the engine is idled for a long and the coolant temperature becomes too low (50-60 deg C), the fuel in the combustion chamber will remain unburnt and will wash the lubrication between piston and liner, causing damage to the moving parts.

Related Read: 10 Extremely Important Checks Before Starting Marine Engines

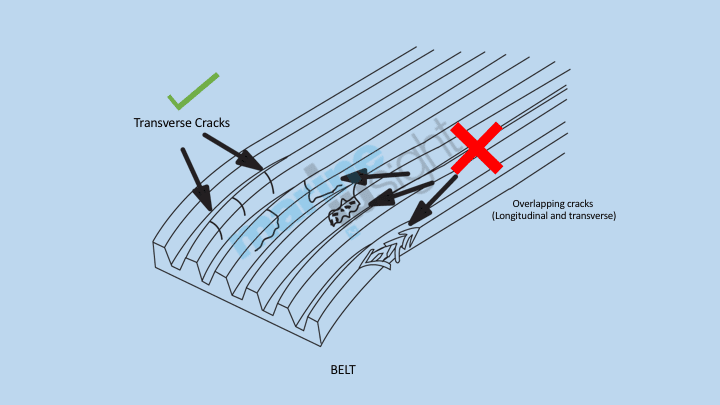

8. The most common problem found in the belts used in the engine to drive the water pump are cracks. Transverse cracks (cracks generated across the belt width) on the surface of the belt are acceptable within the prescribed limit. When the transverse crack is seen intersecting with longitudinal cracks, it is advisable to immediately change the belts.

9. The most common problem found in the radiator fan is the loosening of the screw, which connects blades to the rotor. Never stand in front of the fan (which is set up outside the emergency generated room, to open atmosphere) as a loose screw or broken blade may lead to a personal injury. Never try to rotate the engine using fan blades to avoid injury or breakage of blades itself. Always stop and isolate the engine before tightening the screw on the blade or doing any other maintenance on the fan.

Related Read: 10 Extremely Dangerous Engine Room Accidents On Ships

10. It is always advisable to fill the lube oil filter with lube oil (or fuel filter with fuel oil) before fitting the same to the emergency generator to avoid dry start-up.

11. If an emergency generator provided with compressed air start system, ensure the compressed air unit does not have any lube oil carryover. Prolong carriage of lube oil will form varnish and carbon deposits around the piston of the compressed air chamber and it will not allow it to seal and generate high pressure required for the starting.

Related Read: 8 Things Marine Engineers Must Know About Starting Air System On Ship

12. After a major overhaul, it is important to vent the air trapped in the high-pressure fuel line (of injectors). Each high-pressure fuel line to be vented separately by slightly opening the vent screw provided in the fuel line and by cranking the engine. If the engine needs to be started, ensure not to engage the starter for more than 30 seconds and provide a rest interval of 2 minutes before venting the next injector.

13. Avoid running with oil mixture atmosphere to prevent overspeeding of the generator or explosion of the internal parts. Such atmosphere is possible while loading hazardous cargo on the ship which can go inside the emergency generator through its air intake. Never mix gasoline or alcohol as it can cause an explosion.

Related Read: 10 Situations When Ship’s Generator Must be Stopped Immediately

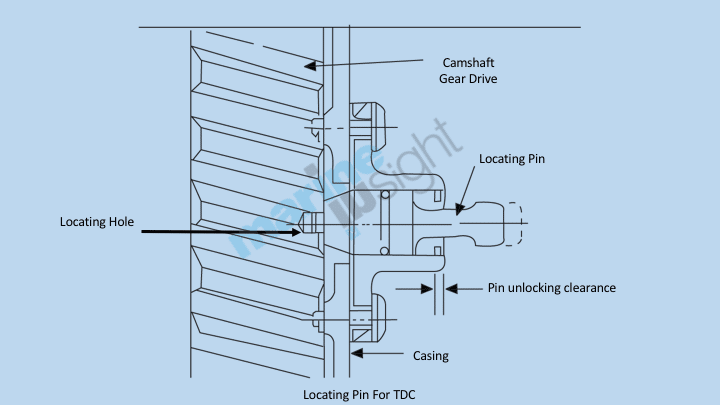

14. After a major overhauling of the engine or when the Top Dead Centre (TDC) of the unit has to be marked, a locating pin is provided in most of the emergency generators which will sit in the hole of the gear drive attached to the camshaft, ensuring the first unit is in TDC. Once the TDC is located, ensure to remove the pin, else starting the generator will damage the pin and the locating hole

15. When the ship is plying in a low-temperature region for a longer duration, there is no provision to keep the emergency generator warm when it is not operational. It is advisable to use synthetic lubricating oil with low-temperature properties with low sulphated ash limit

Related Read: Important Lube Oil Properties to be Considered While Choosing Marine Lube Oil

The make and capacity of the emergency generator vary on ships and the engineer must know the operational and maintenance procedure of the machine thoroughly. The above tips broadly remain the same for all emergency generator models fitted on commercial ships and in case of doubt or assistance, it is always advisable to contact the makers for recommendations.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendation on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

- 10 Situations When Ship’s Generator Must be Stopped Immediately

- 10 Important Tests for Major Overhauling of Ship’s Generator

- 8 Important Points To Note For Maintenance Of Emergency Generators On Ship

- Understanding Different Operational Modes Of Shaft Generator On Ships

- Ways of starting and testing emergency generator

- What’s The Criteria For Reuse or Replacement of Auxiliary Engine Connecting Rod On Ships?

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

An ardent sailor and a techie, Anish Wankhede has voyaged on a number of ships as a marine engineer officer. He loves multitasking, networking, and troubleshooting. He is the one behind the unique creativity and aesthetics at Marine Insight.