Real Life Incident: Hatch Gantry Crane Safety Study

Current gantry crane practice and risk reduction measures are not adequate, finds a report from Dutch Safety Board (DSB).

The in-depth report on issues with gantry cranes was published in July 2022, following a string of accidents involving where crew or shore staff suffered injuries or death. The report was based on six occurrences that involved crushing by the gantry crane due to entrapment, with very similar sequences. Two took place on the same vessel within three years of each other. Readers can find past MARS reports involving gantry cranes at 202201, 202211, 201525, 201460 and 98058.

The report underlines some of the fundamental weaknesses of gantry crane installations and operations. Among other things, it highlights that:

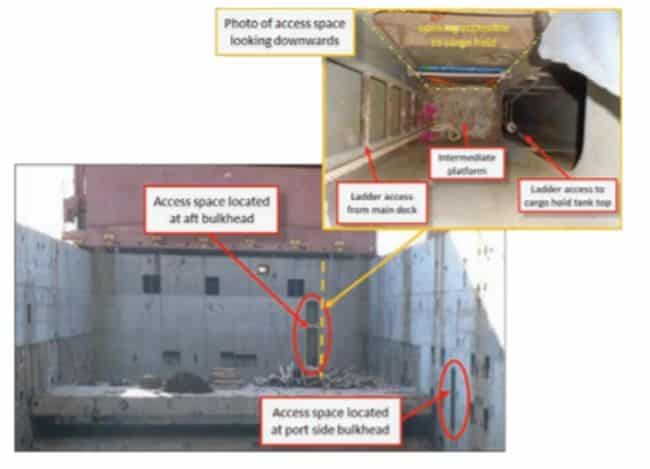

- The crane operator’s field of view is severely restricted and does not allow a proper overview of both sides of the crane’s track.

- The vessel layout allows persons to cross the track of the gantry crane.

- Communication with others is essential for determining if the hatch crane can be operated in a safe manner. Yet, this introduces the risk of miscommunication which was a contributing factor in at least one fatality.

Various measures have been adopted to control bad outcomes, but these appear to still have unacceptable residual risks. For example, having alarms continuously sounding while the crane is operating is well-intended – but they can become routine. Their efficacy will probably decline with time as crew become desensitised to the alarm and qualify it as ‘normal’.

Emergency crane stop buttons are now a common installation. Yet analysis found that in many past occurrences the emergency stop button was not used because it was out of the victim’s reach. Finally, an analysis of the accidents has shown that it is common practice to carry out hatch crane operations at the same time as other operations. In many cases, the victim was not expected to be in the danger zone because he was carrying out operations not related to the use of the hatch crane.

The DSB concluded that current gantry crane practice and risk reduction measures are not adequate. Clearly, a new paradigm is needed. In many industries, working in the ‘line of fire’ is not allowed. Yet, any crewmember stepping across a gantry rail while it is operating is in the ‘line of fire’. It is essential that work is coordinated. A clear framework and agreements for simultaneous yet disparate operations should be established. Without this, the risk of entrapment cannot be adequately controlled.

Lessons learned

- Never cross the gantry crane rails while the crane is in use. If it is necessary to cross the rails, the crane should be stopped.

- Unrelated work on deck or in the holds should not be scheduled while gantry crane operations are taking place. If schedules clash, one or other of the operations should be rescheduled.

Source: The Nautical Institute

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

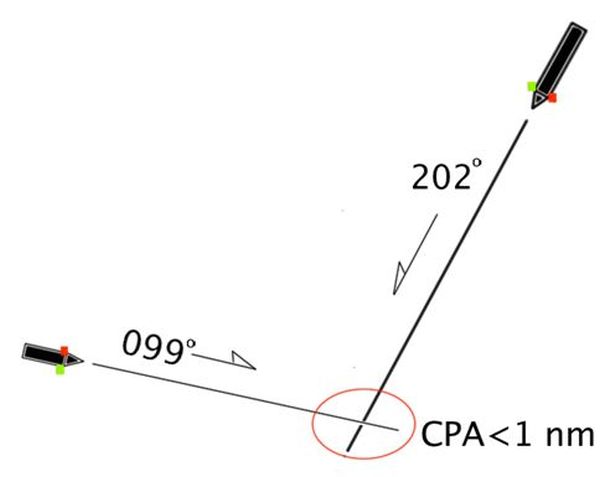

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories