Real Life Incident: Steering Gear Room Flooded Due To Improper Communication

A self-unloading cement carrier was underway in ballast. The OOW began a routine ballast water exchange as required under the ship’s ballast water management plan, using the ballast control panel in the wheelhouse. Additional assistance was provided by the duty rating who operated manual ballast valves, sounded tanks and removed tank access covers in various locations around the ship.

The OOW and the duty rating used handheld UHF radios to communicate with each other and verify the valve status. At one point, the OOW contacted the duty rating and asked that the two after peak manually operated valves be closed. This action was not carried out. The OOW did not confirm with the rating that the message had been received and actioned, so he was unaware that these valves had not been closed.

As the ballast exchange continued, an engine room alarm (aft bilge well high level) activated and the engineer of the watch (EOW) responded. He noticed water flowing over the doorstep through the open steering gear room door. This water drained to the aft engine room bilge, activating the alarm. The EOW discovered the water was coming from a scupper pipe in the steering gear room. He noted that it was salt water but could not find an obvious source in the adjacent spaces.

The ballasting operations were stopped and tanks sounded. Water levels in the after peak tank were found to be higher than normal and an investigation found both valves to this tank to be open instead of closed. Continuing investigations then found water coming up the drain in the CO2 room, a space located on the deck above and atop the starboard side of the steering flat.

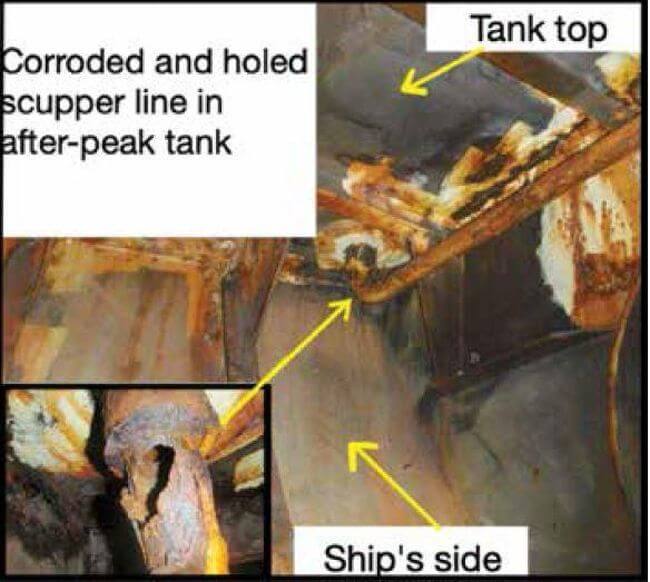

A tank entry and inspection of the after peak tank found a hole in the scupper line from the CO2 room on the outboard side of the pipe just below the tank top. The tank was rarely filled to a depth which covered the holed section of pipe. However, when the starboard ballast tank was full to overflowing, the open valves to the after peak tank allowed this tank to fill as well. As the tank neared full, water covered the hole in the pipe, drained into the steering gear room bilge well and overflowed.

Following this incident, procedures were amended to require the OOW to keep a log of all manual valve operations. Ballasting of the after peak tank was to be conducted only during daylight hours. In addition, a status tracking board was made for the manual valves with moveable pegs showing the status of each valve.

The findings of the official report included:

- The after peak tank filled to a level sufficient for water to leak into the holed scupper line within the tank and drain into the steering gear room bilge well. This overflowed and flooded the steering gear room.

- There was no structured or formalised system to track the status of manually operated valves in the ballast system. Thus, there was no record at the ballast control panel to show the status of the valves when closure of the after peak valves was not actioned or confirmed.

Lessons learned

- Although ballast water exchange may seem a mundane, everyday task, taking in and exchanging large quantities of seawater can have serious consequences if something is not right.

- Use closed-loop communications for safer operations.

Reference: nautinst.org

Do you have info to share with us ? Suggest a correction

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

About Author

Marine Insight News Network is a premier source for up-to-date, comprehensive, and insightful coverage of the maritime industry. Dedicated to offering the latest news, trends, and analyses in shipping, marine technology, regulations, and global maritime affairs, Marine Insight News Network prides itself on delivering accurate, engaging, and relevant information.

- Real Life Incident: Vessel Collision in Good Visibility

- Real Life Incident: Severe Injury To Deck Crew While Leaving Berth

- Real Life Incident: Departure Damage in Very Restricted Waterway

- Real Life Incident: Low Situational Awareness Has High Impact Consequence

- Real Life Incident: Fouled Anchor in a Designated Anchorage

- Real Life Incident: Fire On Barge Carrying Scrap Metal Causes $7 Million Worth Of Damage

Latest Case studies Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories