Cold Ironing Ports – Everything You Want To Know

The impacts of global warming engulf the world, evident in the sudden flash floods, melting glaciers, increasing temperatures and whatnot. Hence all sectors and industries across the globe strive to tackle this grave environmental issue.

Consequently, the shipping sector is not untouched by it; it is a major generator of air pollution and harmful emissions. Per IMO, the shipping industry is responsible for 940 million tonnes of CO2 annually, about 2.5% of the world’s total CO2 emissions. Most of these emissions occur when ships are at sea; some amounts occur when ships are docked.

With the maritime sector responsible for transporting approximately 90% of world cargo, it faces enormous pressure to reduce its carbon footprint.

Hence, the main focus of the shipping industry now is to find green energy solutions, employ eco-friendly technologies and reduce the atmospheric emissions generated by ships to as minimal as possible.

Stakeholders and other shipping industry experts are seeking several smart solutions to achieve these goals of ‘green shipping’.

Besides opting for green fuels, developing efficient energy-saving engines and sustainable shipping technologies like scrubbers, ports offer another solution: cold ironing.

What is Cold Ironing At Ports?

Cold ironing is a term in the shipping industry that came into vogue when all the vessels had coal-fired engines. Once a ship was at port, there was no requirement for keeping the fire lit, and its iron engines could cool down, gradually going cold, hence the word ‘cold ironing’.

However, in present times, the term denotes the process of providing shoreside electrical power to ships berthed at the port while their main and auxiliary engines are turned off.

Cold ironing at ports is a popular concept that supports Green shipping.

While shutting down a ship’s main engines when berthed at port is common, auxiliary engines had to keep running to power the cargo handling equipment and other ship’s services while it was at port.

These engines were the main generators of harmful emissions since they ran on heavy fuel oils or bunkers, releasing SOx, NOx, CO2, particle discharge, noise, and vibration.

Cold Ironing at ports is a viable solution to tackle these issues. It is an anti-pollution measure to decrease air pollution from diesel generators by choosing more eco-friendly shore electric power as the alternative.

In cold ironing, a ship’s engines are turned off when berthed at the port. It is plugged into an onshore power source. The ship’s power load is transferred to the shore-side supply without causing any disruption to the onboard processes and services.

Hence, onboard equipment, refrigeration, heating, cooling, lighting and other emergency equipment receive continuous electrical power from the shore supply source while the vessel carries out its loading and unloading operations.

What Does The Law Say About Cold Ironing At Ports?

Cold Ironing has been recognised as an effective measure for reducing harmful emissions from ships while they are docked at ports; hence laws and regulations in some countries have been put in place so that shipowners and operators abide by the same.

One such prominent law is the EU-approved Directive 2014/94/EU, which mentions that the member states should implement alternative infrastructure like shoreside power technologies by 2025. It would enable all major European ports to provide electricity from land to ships docked at the ports.

The European Union’s TEN-T Program has also stated that in the realm of shore power, funding can help cover 50% of research and 20% of its implementation expenditure.

Is Cold Ironing At Ports Widespread?

As per the EU’s directive, all major European ports must have the infrastructure required to provide cold ironing by 2025.

While Europe is taking significant steps in this direction, most ports in Southeast Asia, Asia and Africa do not have infrastructure that could support cold ironing simply because establishing these facilities requires enormous amounts of money in planning, research and development and implementation. Thus, disparities continue.

Does Cold-Ironing At Ports Cover All Kinds of Vessels?

Not all types of ships docked at ports can avail benefits of cold ironing. Cold ironing is most widespread in the cruise ship industry, generating more emissions than cargo ships. It is also prevalent in the ferry business.

This is because both cruise ship and ferry markets face enormous pressures to reduce their emissions as cruise ship and ferry terminals are often located near historical centres or major cities.

Thus, an increasing number of cruise ships, passenger ships, ferries, LNG Tankers and container vessels use onshore power even when visiting the port only for a few hours.

However, bulk vessels that comprise most of the fleet cannot do so, especially liquid bulk vessels, due to their high energy requirements, strict safety rules and high risk of onboard fire and explosions.

Presently, there is only one operational shore power system in the world catering to liquid bulk vessels. It is situated in Long Beach, California and was designed in 2007 and started functioning in 2009.

It can be used by a specific vessel type, i.e. the BP Alaska Class, connected by three 6.6 kV cables at the vessel’s aft side using its provision crane. Another pier was built to sustain the cable system.

Additionally, the system has been operating for more than a decade without any major accidents, proving that implementing shore power systems for bulk ships is achievable.

Requirements for Cold-Ironing At Ports

- Essential electrical infrastructure at ports so that all engineered and integrated systems fit all kinds of ports.

- Necessary electrical infrastructure on ships, either retrofits or new builds

- Connections and control solutions for personal safety and continuous transfer of power

- Complete onboard solution, including necessary power equipment for connecting the vessel to a shore-side power point.

- Equipment to enable automated power transfer of the ship’s load from its power plant to the shore-side source and back.

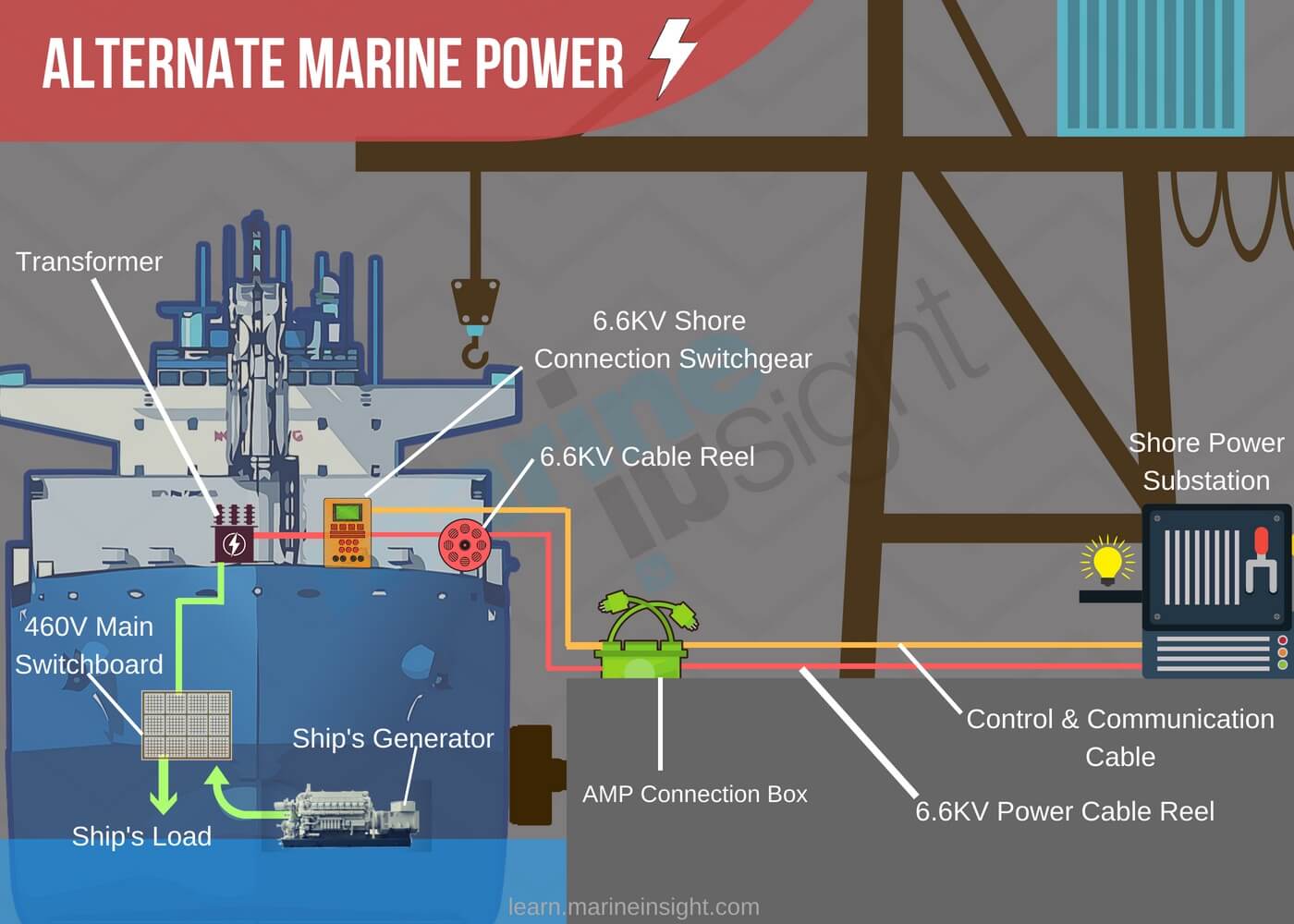

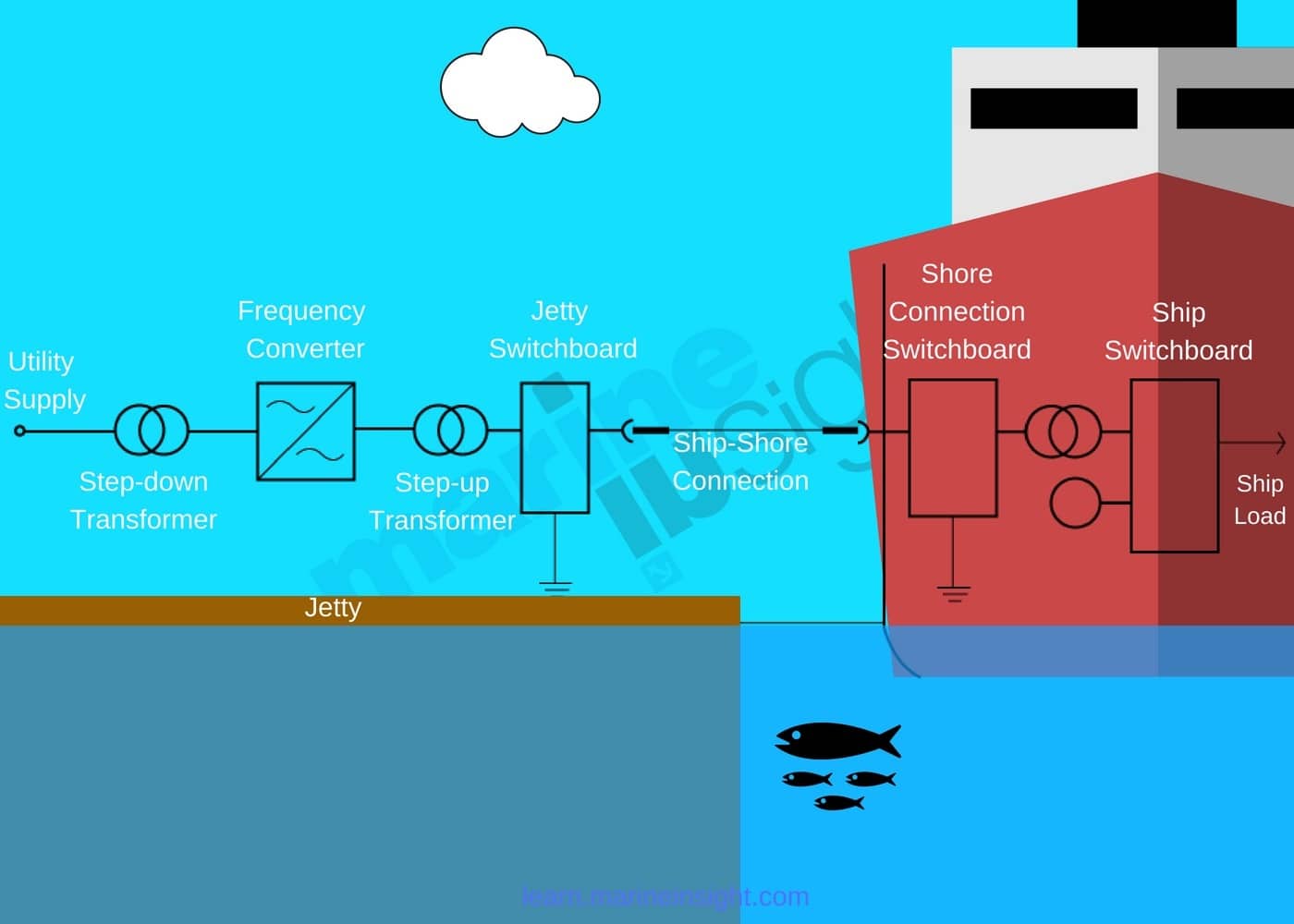

Major Requirements at the Port-

- High voltage power grid at the port

- Frequency & voltage converters and transformers

- Control panels and connection boxes

- Cable reel and connectors

Requirements at the Vessel-

- Transformers

- Power distribution system

- Control panel

- Frequency converter

- Connectors and cable reel

Benefits of Cold Ironing At Ports

Cold Ironing has many social and environmental advantages. If the technology is implemented smartly and correctly at ports, it can help improve air quality near the port areas and significantly reduce carbon emissions, helping lower the port’s carbon footprint.

- It is a highly effective method for making port operations more efficient and environmentally sustainable that can save 30% of carbon emissions and over 95% of NOx and particulate emissions. Per a study, in a 10-hour stop of a cruise ship depending on cold ironing at the port, its carbon emissions decrease from 72.2 to 50.1 tonnes. In comparison, nitrogen emissions fall from 1.47 to 0.04 tonnes, and sulphur emissions reduce from 1.23 to 0.04 tonnes.

- Additionally, another recent study calculated the overall capital cost of installing cold ironing infrastructure at medium-sized ports. The cost was found to be approximately £6.6 m (€7.4 m). The system would save annual emissions of 108 tonnes of NOx, 2.8 tonnes of particulate matter and 4767 tonnes of carbon emissions. The study mentions that in the best-case scenario, the external cost benefits would return the system capital and operating costs in 7 years or 3.5 years if the system was subsidised by 50% by the EU.

Apart from reducing emissions and operational costs, cold ironing also-

-

- Help reduce noise pollution from the vessel.

- Offer better onboard comfort while the ship is docked at the port

- Provide green profile for ship owners and customers

- Decrease lifecycle cost by allowing lower fuel consumption by vessel and reducing maintenance costs

Difficulties or Challenges In Implementing Cold Ironing At Ports

Implementing cold ironing at ports comes with its challenges and difficulties –

- One such is the division of investment cost between the different stakeholders like the shipping line, the terminal operators and port authorities, and the break-even cost compared to bunker fuel.

- Also, the application of cold-ironing in a port might require extensive upgrades of the local and regional power grids.

- Secondly, most shipping companies do not want to invest in refitting their ships since cold ironing is limited to only a few ports. Also, many ships are not compatible and suitable for cold ironing; however, most newly build vessels are pre-equipped with the equipment for cold ironing.

- Another major barrier can arise from the cold ironing infrastructure at port terminals. The terminals need additional electrical capacity, conduits, plugs etc., to accept power cables from a ship. Also, this port equipment must be compatible with the ship’s equipment.

- For example, a huge container vessel might require 1600 kilowatts of power while it’s docked at port, but this power need can vary significantly among different vessels like cruise ships which might need more power. This fact raises the cost since the port electrical infrastructure for cold ironing is very expensive.

- However, incentives for ports to invest in this technology, like the use of emission reduction credits, can be a solution to this issue.

- Lack of standardisation is yet another obstacle leading to technical difficulties. This is about the compatibility of electrical features, as many vessels don’t have the same voltage and frequency needs.

- There is a lack of legislation, and the report titled ‘Key factors and barriers to the adoption of cold ironing in Europe’ points to the absence of strict regulations as one of the prominent reasons why cold ironing is limited to only a few European ports.

- However, strict regulations about the same in the U.S. has led to its successful implementation at the ports of Los Angeles and Long Beach.

- Continuous improvements and uptake of new engines with efficient technologies and fuelling systems is another factor that obstructs the further spread of col ironing technology at ports.

Major Ports Offering Cold Ironing Facilities

Despite the setbacks and difficulties in implementing cold ironing technologies and infrastructure at ports, a few major ports have already implemented this solution.

Let’s see some of the prominent ones offering this facility-

Port of Los Angeles

This port opened its West Basin Container Terminal at Berth 100 in 2004, which became the world’s first container terminal to employ cold ironing. In the same year, it welcomed the world’s first container ship constructed with cold ironing specifications, the NYK’s NYK Atlas.

Port of Long Beach

California made it compulsory that at least half of all the container vessels coming to its ports must use shore-side power while berthed. Hence, in 2014, the port of Long Beach completed over $185 million worth of port power hookups and other necessary electrical infrastructure to employ cold ironing at Long Beach port berths.

Seattle Port

Significant decreases in emissions were recorded at Seattle Port as a result of a successful collaboration between the Seattle Port Authority, Princess Cruises and the Holland America Line.

While cruise ships were at berth, they could plug into the city’s grid, turn off their engines and reduce carbon emissions by 29% and save financially up to 26% per call.

Port of Antwerp

The Port Authority of Antwerp wanted to implement cold ironing at the port. Hence they signed two agreements in 2018 to enable shoreside power supply for seagoing ships in the port.

Apart from the few ports mentioned above, there are other early adopters of cold ironing as well found along North America’s west coast, such as Vancouver port, San Diego, San Francisco and Oakland.

In North Europe, a few Scandinavian nations, Belgium, Germany, and the Netherlands, have also developed cold ironing at their ports.

Cold Ironing is slowly being implemented in Asian ports as well. China has included it in its 12th five-year plan to decrease harmful emissions in its coastal cities.

First cold-ironing port in the Eastern Mediterranean

In a major development for the Mediterranean, the Port of Kilini in Greece became the first facility to offer cold ironing service in the eastern Mediterranean region by establishing an STS electrical supply connection.

The facility received its first customer, a Ro-pax ferry called ‘Fior Di Levante’, which plugged into the region’s first shore power facility on 20th December 2018.

The cold ironing facility was developed through a European co-funded programme involving Greece, Italy and Cyprus, and 6 European ports of Piraeus, Patras, Lemesos, Venice, Heraklion, Igoumenitsa along with the Revithoussa LNG terminal.

Its successful implementation allowed the Kilini port to reduce air pollution and pave the way for other Greek ports to become emission-free facilities in the eastern Mediterranean.

Conclusion

Cold-Ironing is a pioneering technology that can transform worldwide ports into greener facilities.

Given the pressure on the shipping industry to check its carbon footprint and bring about the use of more advanced and sustainable technologies, cold ironing ports could be a useful way of achieving these ‘green shipping’ goals.

Cold ironing can help reduce air pollution, reduce noise and make the process of shipping less harmful to the environment.

However, it must be taken into account that the power grid supplying electricity to vessels from the port must derive power not from the burning of fossil fuels but alternatively from eco-friendly sources like wind energy or solar energy. Only then can the whole process be deemed truly sustainable in its real sense.

However, it can be difficult to achieve this in nations where harvesting renewable energies is cumbersome and not economically possible. Also, it remains to be seen how cold ironing would serve different kinds of vessels with differing energy requirements to improve the sector’s overall environmental impact.

You might also like to read-

- What is Alternate Marine Power (AMP) or Cold Ironing?

- How To Minimize The Risks Of An Electrical Shock On A Ship?

- How Marine Fenders Are Used For Ship Berthing?

- Important Points For Carrying Out Maintenance of Mooring Ropes and Wires On Ships

- Understanding International Waters: Boundaries, Jurisdiction And Legal Implication

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

The article or images cannot be reproduced, copied, shared, or used in any form without the permission of the author and Marine Insight.

Do you have info to share with us ? Suggest a correction

Latest Naval Arch Articles You Would Like:

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

About Author

Zahra is an alumna of Miranda House, University of Delhi. She is an avid writer, possessing immaculate research and editing skills. Author of several academic papers, she has also worked as a freelance writer, producing many technical, creative and marketing pieces. A true aesthete at heart, she loves books a little more than anything else.