10 Important Things to Check While Starting Fuel Oil Purifier on Ships

Every engine room machinery system needs systematic step-by-step starting and stopping procedures to ensure smooth running. The number of things to consider while handling a ship’s machinery system, depends on aspects such as equipment type, making etc.

Starting a fuel oil purifier also involves several important steps and checks. Mentioned below are the ten most important things that must be checked while starting fuel oil purifiers on ships.

1. Check Oil Level in the Purifier Gear Case – Don’t forget to check the level of the oil in the purifier gear case before starting the purifier. If the oil is not up to the required level, insufficient lubrication will damage the gears and other rotating parts (shaft, bearings etc.) in the purifier gearcase.

2. Ensure Break is in Release Position – The purifier break, which is provided near the gear at the bottom of the purifier, must be in the release position. If the break is not released, the purifier will not reach its required speed and the motor current will increase. Moreover, this will also cause wear down of brakes.

3. Open Inlet and Outlet Valves – Ensure that both inlet and outlet valves of the purifier are in an open position. If the discharge valve is not open, the purifier will overflow resulting in oil on the sludge side. Similarly, if the suction valve is not open, the purifier will not get the necessary oil supply.

4. Open the Tank Valves – Check the valves of the specific tank (service or settling) where the discharge from the purifier is to be sent. If the tank valve is not open, the backpressure in the line will increase leading to overflowing of the purifier.

5. Check the Level of Operating Water – If there is a separate operating water tank provided, check the water level in the same. If the operating water is not sufficient, the purifier bowl will not lift, resulting in the sludge ports remaining in the open position.

6. Check Feed Pump– Check that the purifier feed pump is running properly, along with oil pressure and temperature. Some purifiers are provided with attached gear pumps for supplying fuel to the purifier. In such cases, ensure that the oil temperature is enough to ensure the smooth running of the gear pump attached (via a shaft and key). If the temperature is low, the oil viscosity will be high, which may lead to breaking of the key that connects the shaft and the gear pump, thus stopping the oil supply.

7. Ensure Heater Valves are Open – Ensure that the fuel oil valves to the steam heater are opened before opening the steam line valve near the heater. If the steam is opened first, the tubes can get damaged, leading to the ingress of water in the oil.

8. Increase the temperature – Increase the temperature of the fuel oil to the limit provided in the digital control panel of the purifier. In all automated purifiers, the control panel is provided with a pre-set minimum temperature limit. The purifier will not start until the fuel oil reaches this temperature.

9. Check for any abnormal sound or vibration– If you know your machinery extremely well, you will be able to tell if there is any abnormal vibration or sound during starting. Shut the purifier immediately in such conditions and rectify the fault completely before starting it again.

How to check? – Take a screwdriver, touch the metal end to the purifier body, and the second end to your ear. You will be able to hear the smooth running of the inside parts more clearly.

10. Check Solenoid Valves – Check all solenoid valves are operating properly by checking the lights on the solenoid valves. If the lights are not working properly, take a screwdriver and bring it near to the top surface of the solenoid valves. When the solenoid starts working, the screwdriver will be attracted to the valve body due to the magnetic effect.

If solenoid valves are not working properly, the purifier will also stop operating. For e.g., if the operating water line solenoid valve is not working properly, the bowl will not lift, or if the high-pressure water line solenoid is not working, then the purifier will not de-sludge.

The Ultimate Guide to Operating Engine Room Machinery is a premium ebook that explains starting and stopping procedures of all engine room machinery and systems on ships.

Disclaimer: The authors’ views expressed in this article do not necessarily reflect the views of Marine Insight. Data and charts, if used, in the article have been sourced from available information and have not been authenticated by any statutory authority. The author and Marine Insight do not claim it to be accurate nor accept any responsibility for the same. The views constitute only the opinions and do not constitute any guidelines or recommendations on any course of action to be followed by the reader.

About Author

Raunek Kantharia is a marine engineer turned maritime writer and entrepreneur. After a brief stint at the sea, he founded Marine Insight in 2010. Apart from managing Marine Insight, he also writes for a number of maritime magazines and websites.

Do you have info to share with us ? Suggest a correction

Latest Marine Technology Articles You Would Like:

- 10 Harmful Effects Of Impure Air On Ship’s Machinery

- 10 Important Things to Check While Starting Fuel Oil Purifier on Ships

- 10 Noteworthy LNG-Powered Vessels

- 10 Points for Efficient Turbocharger Operation On Ships

- 10 Practical Tips to Handle Engine Room Pumps

- 10 Precautions to Take Before Operating Controllable Pitch Propeller (CPP) on Ships

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

1. If the operating water is given through a pressure regulator, make sure the water pressure is maintained properly. Too much pressure also can keep the bowl open and lead to fuel overflow.

2. Make sure there is no airlock in the fuel line which can lead to loosing suction of the feed pump.

1) Ensure automatic alarm/trip monitoring system for purifier is in on position ,otherwise there will be no safety alarms and trips operational and which can lead to serious problems.

2) Check the amps that the purifier motor is drawing is with in the permissible normal range.

2) In case of inspecting purifier for overflowing or leakage from Inspection port,check the timer panel that it should not be near to desludging interval and also while inspection one has to be very careful or else he can get serious burns.

How about if the purifier run in low feed rates? what will happen to the clean oil? e.g the purifier rate for the certain gravity disc is 1300l/h but the feed bring down till 350 l/h. Is there any problem will occur later on? Will the cleaned oil contaminate with water? this feed is for G.E Lo purifier. same temperature maintain for both process. 80-90.

Name all separate parts of purifire

what will happen if H,F,o purifier inlet tem; is increased and decreased from allowed temp;.? pls help,,,,,,,,this is the qstn, asked for oral exam.

Dear sir

Can i knew the meaning of “FOPX” in Alfa Laval FOPX separetors?

please can you tell me where is water seal, is it between discs ( around them ) or between discs ( plates ) and top disc, I need that answer for 3 rd class, and I can”t find the answer anywhere, thank you.

Why we delay the fuel inlet after starting the purifier, if delay is not there then what will happen?

@Shuvam: The purifier must reach its rated speed to form the interface and proceed to the purification process.

Imagine you just started the generator and put the load on it immediately!!! The next thing will happen is a blackout.

My purifier is leaking oil from water side…iam running purif in port in sailing this problem was not there.plz help

Can someone list down the common causes of abnormalities in Purifier? You can e-mail me at hfcvilla@gmail.com, your help is really appreciated, thank you!

During starting of my ALFALAVAL S826 HFO purifier i have no problem but after 1st de-sludging and automatic restarting the purifier there have no pressure on delivery pressure or (PT4). I check already the parameters on the panel screen and compared to the other 1 hfo purifier, (same parameters)

Do you have any idea what is the main cause of this problem pls email me at RUFFA_GORDULA yahoo.com

your reply is appreciated tnx……

john says

check first if the bowl is closed. If not, the next thing you do is check if you have supply of operating water. If you have it means problem is inside your bowl. You can dismantle check for the seal ring maybe the indention is already deep. You check also the o-rings in operating water side which are related in closing the bowl.

On a oil purifier on resuming normal purification after automatic desludging the equipment frequently experience high temperature alarm. What would you do to avoid re-occurrence.

A. Increase capacity through purifiers

B. Decrease capacity through purifier

C. Lower the setpoint of oil temp

D. Fit or adjust time delay on high temperature alarm.

@Hassaan: We need to increase the capacity through purifier which will reduce the temperature.

Gravity Separation

Consider gravity separation, as occurs in a settling tank, over a gradual period solids such as sludge, dirt, etc., will settle out at the bottom of the tank. The heavy liquids, such as water, will settle out above the solids and the lighter liquids, such as oil, will be at the top of the tank. The application of heat will speed up the separation process.

Separation occurs due to the specific gravities or densities of the liquids and solids.

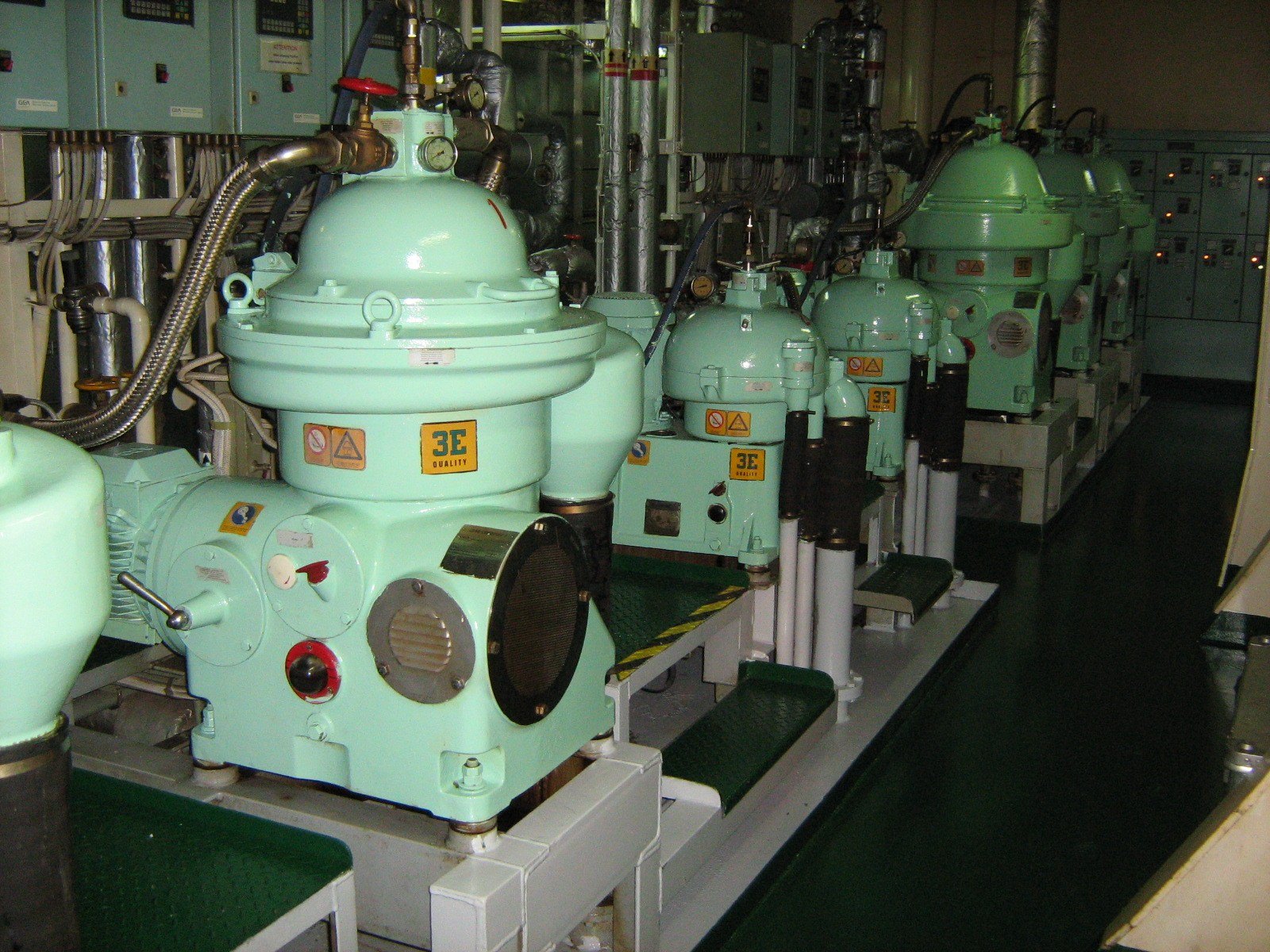

Centrifugal Purifiers

In the above case it is gravity that is responsible for the settling out and this takes quite a while. If the gravitational force is increased, by using centrifugal force, the separation effect is much greater. This is shown in figure below by imagining settling tank on its side and rotated, which is the basic principle of centrifugal purifiers.

The centrifugal purifiers or separator consists of a bowl containing a set of discs stacked one on top of the other. The dirty oil flows down the distributor and up through the holes in the discs.

What is gravity disc ?

The gravity disc is important part of purifier, which set the location of the oil, and water interface line, which is variable according to the maker’s design.

How to choose the correct size of gravity disc ?

Correct size is selected using:

Separation temperature

Density of oil at this temperature

Desired throughput of oil and by using of nomogram from the purifier manual.

What is paring disc ?

It is a stationary impeller mounted in a chamber at the neck of the bow.

Its function is to convert the rotating energy of the liquid into a pressure head.

What about water washing ?

Water washing is widely used techniques to remove acids, salts, and other impurities from the oil.

The oil must be straight mineral oils or without dispersant additive oils.

Water should be injected into the oil before purifying at a rate of between 3 to 5% of the oil flow that is continuously renews the water seal in the purifier bowl.

The oil temperature should be around 75 °C and water temperature about 5 °C higher than oil.

It can be done continuously or intermittently.

What is steam jetting ?

By blowing steam into the engine lube oil just pair to its purification.

Coagulation of colloidal carbon will occur.

Purifier will remove this carbon more effectively.

Compare purifier and clarifier ?

Purifier

1. Remove water and suspended solids particles from oils

2. Two outlets water and clean oil

3. Gravity disc on top

4. Blind disc on the top of disc stack

5. Sealing water required

Clarifier

1. Remove finer and lighter particles from oil

2. One outlet for clean oil

3. No gravity disc only sealing ring

4. Blind disc at bottom.

5. Sealing water not required

How do you change purifier to clarifier ?

1. Open up the purifier and set the blind disc at the bottom of the disc stack.

2. The water outlet is blocked by a seal on the gravity disc.

3. Blank off the sealing water inlet line.

What is purifier, clarifier ?

Purifier is a centrifuge, which is arranged to separate water and solid impurities from oil.

Clarifier is a centrifuge, which is arranged to separate finer solid impurities from the oil.

How to change purifier from HFO to DO ?

1. Replace the gravity disc, which is smaller than the heavy oil

2. Open heater by pass vale.

3. Close the FO heater steam in/out valves.

4. Open heater drains v/v.

5. Pure DO purifier cannot change to HFO, it has no heater.

6. Pure clarifier cannot change to purifier, it has no water outlet.

Why multidisc provided inside purifier ?

1. To separate the liquid into thin layer & create shallow settling distance between discs.

2. Improving separation of oil from heaver liquids & solids particle

Cause of excessive vibration on purifier ?

1. Sludge too much inside the bowl

2. Foundation damper & spring failure

3. Bearing failure

4. Worn gear

5. Uneven wear of frictional clutch

6. Motor speed too high or too low

What are reaseons for purifier over flow ?

1. Incorrect purifier disc size (inside diameter too large)

2. Too low fuel oil temperature

3. Too much rate of throughput

4. Too much sludge inside the bowl

5. Low speed (rpm) of bowl rotation

6. Sealing water failure

7. Operating water failure

8. Worn out main sealing ring

Why purifier is not building up speed while running ?

1. Improper touching with friction clutch (worn out frictional clutch)

2. Touching with break

3. Excessive sludge in the bowl

4. Bearing failure

5. Motor running at overload

6. One phase power failure (Single phasing)

7. Sump oil level too high

8. Vertical shaft and horizontal shaft are out of alignment

How to adjust purifier bowl height ?

By shim by bowl body

Effect of reduced purifier bowl height ?

Oil goes through the water outlet.

Why need sealing water ?

To seal the water outlet & to prevent the overflow of oil from the water outlet.

WHAT STEPS WILL BE TAKEN , IF A PURIFIER FAILS TO DESLUDGE WHEN OPERATING IN AUTOMATIC MODE ?

Fuel oil purifiers normal:

Feed rate?

Temperature?

Flow rate?

Hello, can help me on wisfalia HFO purifier when it’s start to rise the RPM to 10k to 11k it’s making noisy on the bowl . We already check bearings in the motor side and bowl . It’s still making noise. Tnx

Is the noise only during that RPM or remains all the way?