The Writer of ‘I Don’t Want to Miss a Thing’ Never Thought Aerosmith Would Sing It

Some classic rock songs come from unexpected places. For example, Aerosmith’s “I Don’t Want to Miss a Thing” was written by a songwriter known for writing romantic power ballads for movies. The writer in question didn’t think the song could suit Aerosmith.

Aerosmith’s ‘I Don’t Want to Miss a Thing’ was supposed to promote an action movie

“I Don’t Want to Miss a Thing” was written by Diane Warren, a songwriter known for writing power ballads for movie soundtracks. She gave us hits like Celine Dion’s “Because You Loved Me” from Up Close & Personal and Starship’s “Nothing’s Gonna Stop Us Now” from Mannequin. During a 2021 interview with Rolling Stone, Warren said the history of “I Don’t Want to Miss a Thing” begins with another one of her songs, LeAnn Rimes’ “How Do I Live.”

“How Do I Live” was meant for the action movie Con Air, a big-budget action flick by producer Jerry Bruckheimer. “Jerry asked if it was OK to put Tricia [Yearwood] on [‘How Do I Live’],” Warren recalled. “And I said, ‘Yeah, but I can’t pull it from LeAnn. Even if Trisha does it for the movie.’ And then Jerry was like, ‘No, you have to pull it from LeAnn.’ I couldn’t do that. Jerry was like, ‘I’m never gonna work with you again.'”

Bruckheimer later made another action movie, Armageddon, that featured a Warren ballad called “I Don’t Want to Miss a Thing.” “Remember, he said he wasn’t gonna work with me ever again, a year before?” Warren recalled. “He changed his mind. So I went back and wrote the song. And never in a million years thought Aerosmith would do it.”

How Diane Warren reacted to Aerosmith’s version of the song

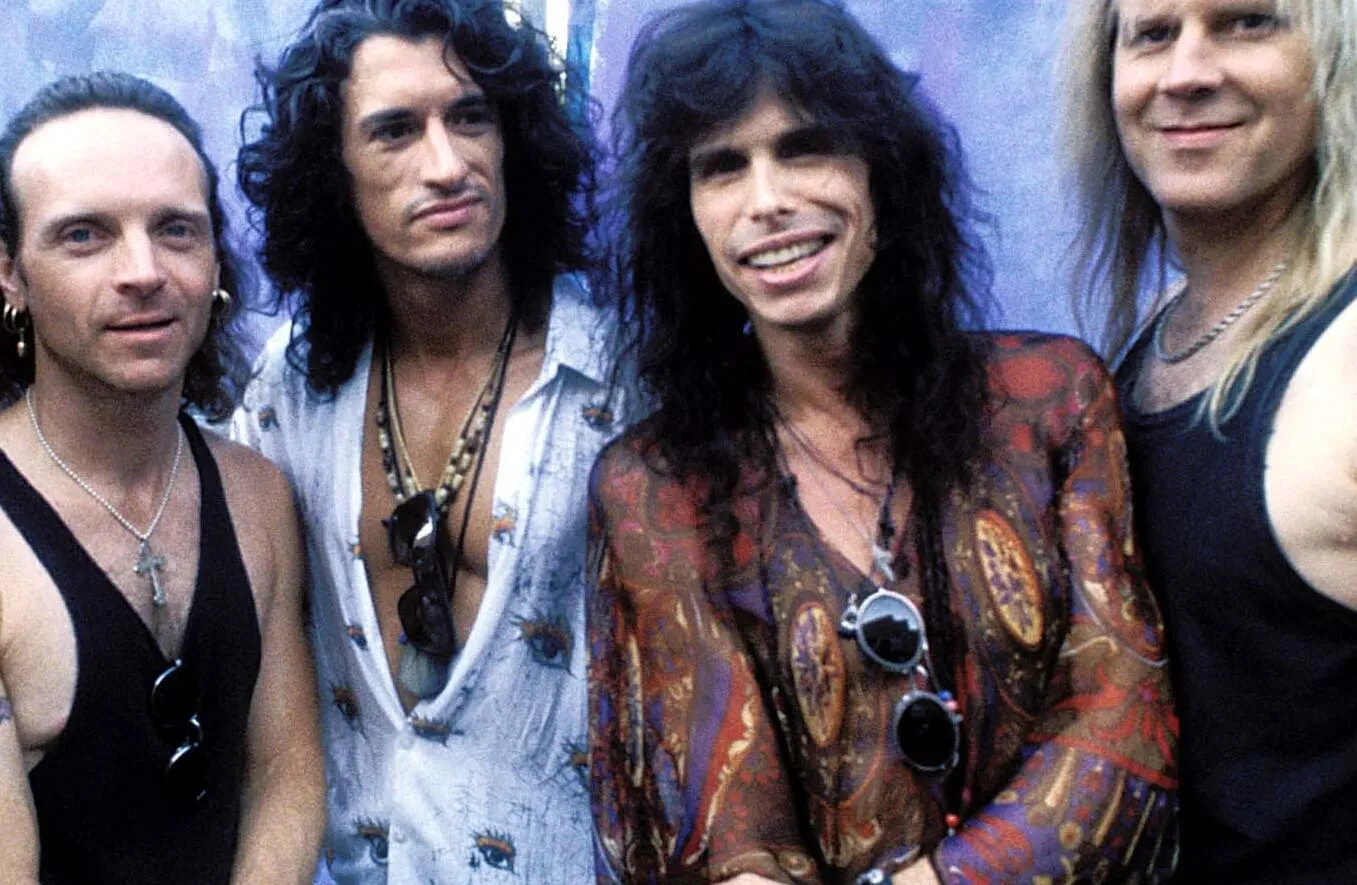

Warren had different expectations for “I Don’t Want to Miss a Thing. “I kind of thought a female vocalist would end up doing it, but it’s so much more powerful with Steven Tyler — him being that vulnerable in the song really worked,” she said. Aerosmith had put out power ballads before, such as “Dream On” and “Crazy,” but “I Don’t Want to Miss a Thing” is a lot more sentimental.

Warren recalled being blown away by Tyler’s vocal performance on “I Don’t Want to Miss a Thing.” In retrospect, she was very proud of the song. She believes it should have won the Grammy Award for Record of the Year. Interestingly, a lot of Aerosmith fans (and classic rock fans in general) take issue with “I Don’t Want to Miss a Thing” for being closer to easy-listening music than Aerosmith’s other hits. That might explain why the track didn’t rack up any Grammys.

‘I Don’t Want to Miss a Thing’ was the band’s only chart-topper

Regardless of the critical reception of “I Don’t Want to Miss a Thing,” it performed very well with the public. The track became the band’s first and only No. 1 single, topping the Billboard Hot 100 for four weeks and lasting on the chart for 20 weeks altogether.

The ballad appeared on some editions of the album Nine Lives. That record reached No. 1 on the Billboard 200 for a week. It lasted on the Billboard 200 for 77 weeks in total.

“I Don’t Want to Miss a Thing” was a somewhat controversial foray into sentimentality for Aerosmith. Warren was surprised they even touched the song.