Below Deck

Below Deck

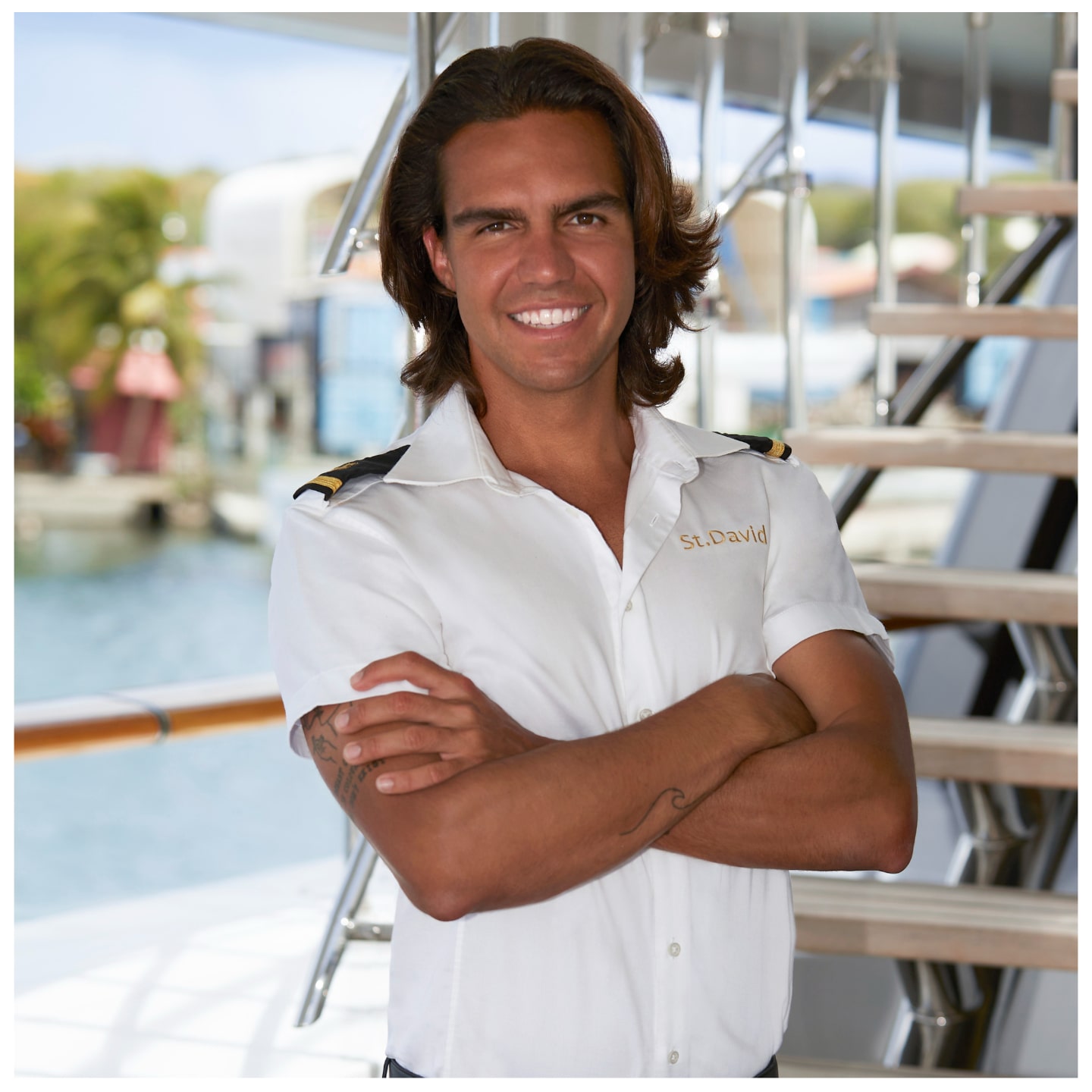

Below Deck is a Bravo reality TV series that follows crew members who live and work aboard a yacht as they sail off to new locations.

Each episode features a new set of passengers on yachts well over 100 feet as they travel to exotic locations and chronicles the crew while they serve elite clientele aboard the luxury vessels.

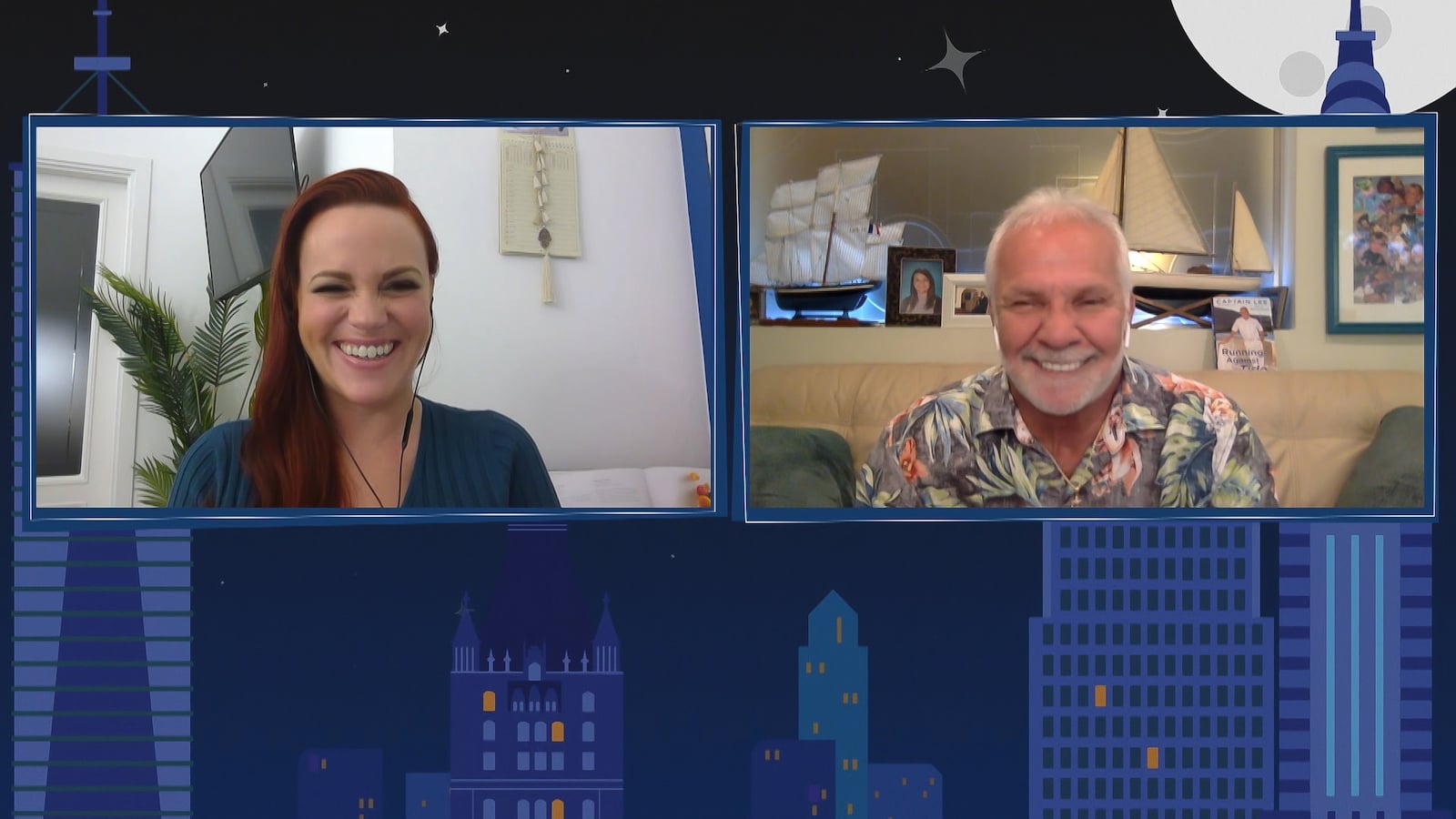

TV Genre: Reality-TV Premiere Date: July 1, 2013 Where to Watch: Peacock, BravoTV Cast: Lee Rosbach, Eddie Lucas, Rachel Hargrove, Heather Chase, Jessica Albert Spinoffs: Below Deck Mediterranean, Below Deck Sailing Yacht, Below Deck Adventure, and Below Deck Down Under

TV Genre: Reality-TV Premiere Date: July 1, 2013 Where to Watch: Peacock, BravoTV Cast: Lee Rosbach, Eddie Lucas, Rachel Hargrove, Heather Chase, Jessica Albert Spinoffs: Below Deck Mediterranean, Below Deck Sailing Yacht, Below Deck Adventure, and Below Deck Down Under