3 Important Calculations Every Marine Engineer Must Know On Ships

In ship’s engine room, a number of gauging instruments display various important parameters such as level, pressure, temperature etc. But there are some essential parameters which cannot be read directly through any instrument as they depend on a number of dynamic factors.

This demands the marine engineer working onboard ships to do some formula based calculations by considering all those factors and with possible available inputs. Of all the important calculations that are to be done on board ships, there a few ones which marine engineers must know without fail.

Related Read: 8 Engine Terms Every Marine Engineer Should Know – Part 1

Following are 3 important parameters that are most often required to be calculated by marine engineers for record-keeping:

1. Bunker Calculation:

Bunker terms to fuel oil in the maritime industry. Bunker quantity calculation is the most important calculation which every marine engineer should be familiar with throughout his career. Bunker fuel, being a highly valued product, has to be very carefully and accurately calculated for determining the quantity.

The volume of a definite quantity of bunker increases with an increase in temperature whereas its weight remains the same. For this reason, the bunker is always ordered and measured in weight and not by volume.

Related Read: The Ultimate Guide to Fuel Oil Bunkering Process on Ships

Also, all the energy and efficiency calculations of fuel onboard ships are calculated in terms of the mass of the fuel rather than its volume. (Calculation of bunker fuel quantity in weight involves many factors to be considered making it more complex.)

Mostly, the fourth engineer will be the deputy of the Chief engineer for receiving bunker & measuring the bunker quantity for maintaining records.

Mentioned below is the procedure for measuring and calculating the bunker quantity:

- Once the total quantity (tonnes) of bunker fuel to be received is confirmed, take a sounding of ship’s bunker tanks & calculate the available quantity of fuel oil onboard to formulate a bunkering plan denoting how much tonnes of fuel to be bunkered on each tank & the tank sequence of bunkering.

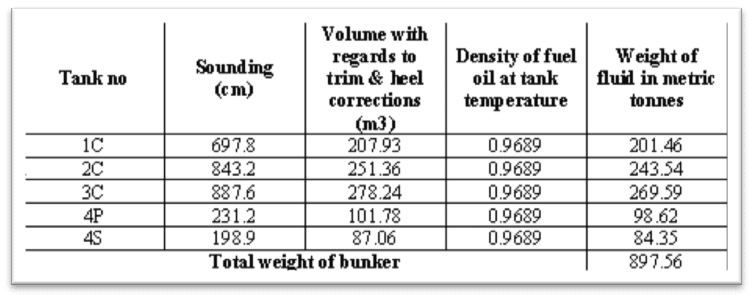

- Before commencing of bunker operations, confirm the temperature at which the bunker is to be received and note down the standard density of the fuel oil. With this parameters calculate the volume of the bunker to be received in each tank as per bunkering plan and note down the final sounding level of each tank after bunkering using the capacity table for the ease of stopping & change over to next tank.

Related Read: 15 Practical Tips For Bunkering and Storage of Fuel Oil On Ships

The basic formula used for calculating the bunker quantity in weight is:

Mass = Volume x Density

- It is to be noted that in the above formula, the density and volume of bunker fuel should be known at the same temperature.

- After receiving the bunker, take sounding/ullage of all the bunker tanks using sounding tape and note down the tank temperature. Use sounding paste in the tape while measuring distillate fuel such as MDO for easy reading.

- The ship always does not float with an even keel so the floating conditions of the ship such as trim and list should be well noted while taking the sounding of bunker tanks.

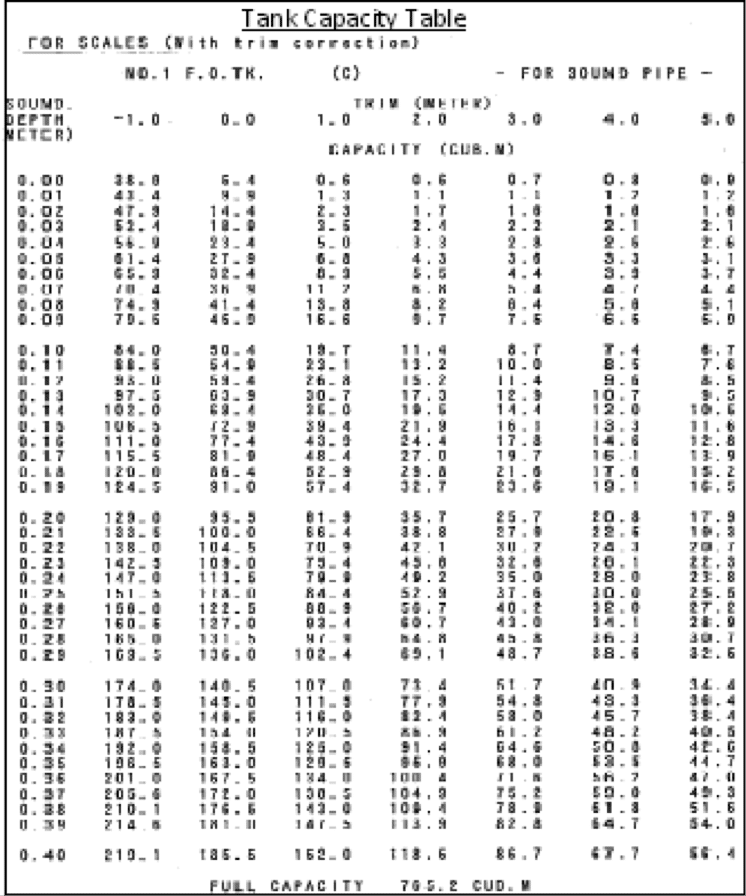

- Every ship is provided with a tank capacity table in which each tank capacity in volume is marked against the successive levels of sounding/ullage with correction factors under various trim and heel conditions of the ship. The volume of fuel oil at tank temperature for the corresponding tank sounding is thus measured using tank capacity table, which gives the actually sounded volume.

- The density of fuel oil (in kg/m3) at a standard reference temperature of 15⁰C is always provided by the supplier in Bunker Delivery Note. With this, the density of fuel oil at tank temperature can be determined using ASTM table or using software most commonly installed on all ship’s computer.

The formula used to calculate the Temperature Corrected Density is:

= (Density of Fuel Oil @ 15⁰C) x [1- {(T-15) x 0.00064}]

Where:

T = temperature of oil in bunker tanks in degree Celsius,

0.00064 = Correction factor

Since the bunker oil is normally supplied to the vessel at a temperature higher than 15⁰C, the formula used for calculating the bunker quantity in weight will be:

Metric Tonnes = (Actual Sounder Volume) X (Temperature Corrected Density)

The corresponding values of each tank are tabulated for easy reading and the total weight of bunker quantity is calculated.

2. Specific Fuel Oil Consumption (SFOC):

Specific fuel oil consumption is the measure of the mass of fuel consumed per unit time to produce per KW. The marine engine efficiency is usually determined using the SFOC.

In order to achieve accuracy, the fuel consumption and power developed is always measured over a suitable time period on a good weather. The formula used for calculating SFOC is:

SFOC (g/kwh) = Mass of fuel consumed per hour / Power developed in KW

- The readings of the flow meter to the main engine should be noted over the specified time interval say 1 hour. With the difference in readings, the volume of fuel consumed is obtained. It can also be measured by noting down the HFO service tank reading provided the oil is being supplied only to the main engine.

- The mass of the observed volume of fuel consumed can be determined by following the above-said bunker calculation procedure.

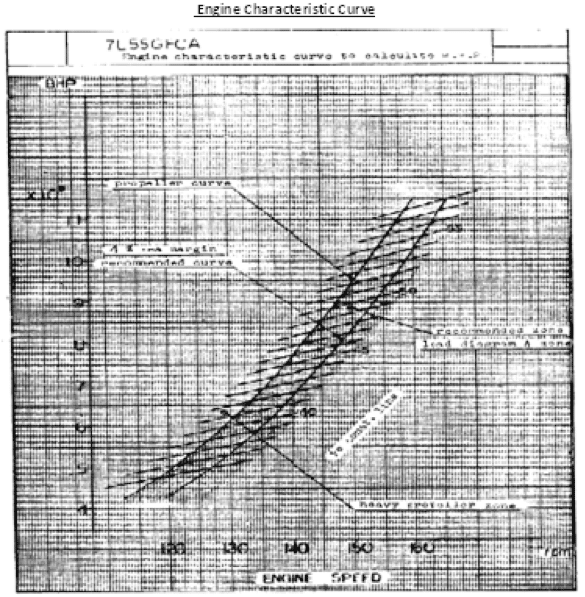

- The horsepower can be measured using dynamometer if fitted on the shaft of the engine which will indicate the BHP in the digital indicator. If not, the horsepower can also be calculated using engine rpm and average pump fuel index with the aid of engine characteristic curve of various sea trials which is supplied by the manufacturer. However, the calorific value of the fuel used for sea trial may differ and hence compensation factor has to be determined to obtain the accuracy in calculation.

Related Read: 14 Terminologies Used for Power of the Ship’s Marine Propulsion Engine

3. Percentage of Slip:

Slip is considered as the difference between the speed of the engine and the actual speed of the ship. It is always calculated in percentage. Positive slip is influenced by various reasons such as fouled bottom or hull part which offers resistance to the movement of the ship, environmental factors such as water current and wind against the ship direction. The slip may be negative if the ship speed is influenced by following sea or wind. Engine slip is calculated daily onboard the vessel and recorded in the logbook.

Related Read: Various Methods Used to Minimise Resistance on Ship’s Hull

Engine distance – Observed distance

Percentage of Slip = ————————————————– X 100%

Engine distance

- The actual distance (nautical mile) covered by the ship from noon to noon is measured using the ship’s log.

- The total revolutions of the propeller from noon to noon is obtained using the revolution counter. The engine distance can be calculated using the pitch of the propeller provided by the manufacturer. Care must be taken in the unit conversion of the pitch from meter to a nautical mile (in general 1 NM = 1800m).

Engine distance in nautical mile = (Pitch x revolutions per day)

Obtaining the accuracy of value in all the above calculations are always challenging onboard as the parameters recorded are more sensitive to dynamic conditions of the ship and also depends on various environmental factors.

Related Read: 8 Engine Terms Every Marine Engineer Should Know – Part 2

Over to you…

Do you know any other important calculations that can be added to this list?

Let us know in the comments below.

References & Image Credits:

M.V. Jag Rahul – Ship’s tank capacity plan manual.

M.T. Jag Preeti – MITSUI B&W – Operation & Data Manual

Reeds Naval Architecture for Marine engineers.

Latest Shipboard Guidelines Articles You Would Like:

Do you have info to share with us ? Suggest a correction

Subscribe To Our Newsletters

By subscribing, you agree to our Privacy Policy and may receive occasional deal communications; you can unsubscribe anytime.

Web Stories

It is all correct. Whan i miss is the comparison of the fuel comsumption with a reference. The reference is the specific fuel consumption on test bed at the manufacturer. Here the fuel consumption as well as the engine performance data are measured, and converted to the ISO condition. It is important for the actual situation also to record the engine performance data and to convert them to ISO, otherwise you compare apples with pears. There are not many tools available for this manouver. You can do it all manually, but it will consume a lot of time. At our web site you can see out tool, where you get the iso correction and comparison instantly when entering the performance data.

Really, and they havent automated it yet?

is correction factor of 0.00064 is applicable for all oil like heavy oil ,diesel oil etc……..

Very good information

Great work ananth… very useful info…

0.00064 is not a constant correction factor. This defends on quality of every oil bunkered. Normally on the BDR, density is given at 15 deg cent. An estimated density at higher temp is also mentioned on the BDR e.g. Density at 15 deg cent = 0.9891, density at 40 deg cent = 0.9687. Temp diff then will be 30 and density is 0.0204. The correction factor then should be [0.0204/30 =0.00068 ton/deg of temp rise.

its Very Useful and easy understanding article Mr.Ananth. Keep Writing..

at last I found what I need as long this time thank to you

yr info.as stars for any one get lost in the tech. desert,SFOC.is the most interesting factor must but in consideration to avoid any commercial disaster ,i mean, the fuel is big problem for expenses so,sfoc very important

Great work congrats……

Hi Ananth,

A very nice and useful post which should come useful to any engineer who has to handle bunkers.

Keep up the good work 🙂

Dear Ananth,

Very good topic discussed .

I feel there is a small correction in slip it shold be positive slip .

Negative slip influenced by favarouble current and henc lesser cons.

With rods,

AJAIKUMAR

Thank you Ajai,

Well noted and corrected the typo.

Nice Job Buddies.

i m a 4E …. very informative for me .. but i also read smvr abt subtracting 0.0011 from density@15 deg celcius for sm correction factor for buoyancy in air .. pls advice

I found what I need at this time!! 10Q Ananth T.

thank u for impacting d public with this knowledge. many marine engineers has gotten problems in fuel consumption calculations. but with what you have explained. l believed our jobs as Junior officers is made easy.One God.

A really good post. As a 3rd Eng, I really found this very interesting since normally I don’t do the bunker plan but only the Chief Engineer. Anyway it is not so complicated after you have got some experience when you load bunker.

Good informatn . . .kepit up nd keepgoing. .

In the slip calculation you say observed distance should be ships log distance…. is it correct? As per my understanding it is Days Run or GPS distance nowadays….. Log distance will give huge variations in the actual slip…

very nice

It is good to have all important calculations in one page. I have a suggestion to you, that you can add the calculation for bunker requisiton, co2 bottle weight measurement, scba time duration calculation,etc.

Great article.

Great, very good information ,Keep it continue.

It is very useful.

what is the theoretical distance and why it is considered as theoretical?

Useful consolidation of standard things we all need to remember. Thanks. Another useful number to always be able to calculate is the G of M for a given load condition and sea/season. Just a thought

i like the sharing info about bunker calculation and main engine performance data.

You dont include the trim correction and the heeling correction before you can calculate the fuel onboard

Very Helpful.

In what regulation is it referred to?

thanks for such information…

I would like to understand what is the diff. between engine and the actual slip ?I understood that the engine slip can be cavulated by the given formula but what about the actual slip how can I opt-in it

Nice to c a writing from marine engineer onboard ship… Pretty simple n clear details

Fantastics subject

Hi, Just call me Mariners friend, engage for 26 years in petroleum survey and bunker survey. I should say the reason why most bunker barge supplier doesn’t want surveyor on board the vessel? Because of that formula used by most engineers when receiving bunkers. Considering the standard formula we are using for bunker calculation at any port, your total observed volume = 926.37 cm; density (without correction of 0.00064) = 0.9695; let say temp. at 45 deg C. Using ASTM TAB. 54B and ASTM TAB 56 your actual metric tons received are = 878.168 surveyor’s calculation.

therefore 878.168 mt.- 897.56 mt.= (-)19.392 mt difference. my friend you have had less bunker fuel received. as per surveyors calculation. However, most surveyors are adamant to change his figure. Hope it helps. thanks! And Happy voyage to all.

good one sir

If you are using the log distance (distance through the water), as you suggest, then current should have no effect on slip. Using a GPS distance will give meaningless figures from a performance point of view, the vessel would be moving over the ground even if the engine was stopped because the water in which it is sitting is itself moving over the ground.

Distance over the ground (GPS distance) cannot be used if the slip calculation is required to provide a meaningful figure, using the log distance (the distance the propellor actually moves the vessel through the water) provides an almost true indication of the work actually done by the propellor, with wind and sea state being remaining sources of error.

is there a book that covers all this information regarding fuel calculation, on board ship, ex. bunkering, port to port consumption, ordering fuel, regulations etc.

May I know engine consumption fuel oil per an hour in low idle without gear box? If the engine 350HP.

Thanks Mariners friend for that great info. Actually, I’m a fresh graduate frm the Petroleum Training Institute, Nigeria. I studied petroleum marketing. I wnt to pursue a career in petroleum survey and I have keen interest. With the foundation that got frm schl on petroleum and its products measurement and analysis, I have been doing some study online on petroleum measurements, but the volume correction factor is given much worry. I see you have great wealth of experience in petroleum measurements, pls I need your help and guidance on this. I so much love petroleum measurements with passion.

That was a great info MTvital. I’m fresh graduate of Petroleum Marketing Technology frm The Petroleum Training Institute, Nigeria. I have basic knowledge in petroleum and its products measurement and analysis, but my keen interest in petroleum measurements (surely) has been making search the internet often for information that can help improve myself in new career that I’m now pursuing. The volume correction factor for petroleum is really giving me serious concerns. Pls MTvital, I can tell that you have vast knowledge in field, kindly guide me during this petroleum survey. Thanks.

Every bunker tank’s calibration table is based on a certain range of densities of oil to be carried. So if there is a conversion of a bunker tank from heavy fuel to light fuel calibration table must also be changed because for a given mass heavier fuel will acquire less volume and lighter one will acquire more volume.

Very usefull topic. Can u state more clearly how to corect the volumetric with trim and heel

Completely support previous comment regarding the vessel slip.

It’s to be calculated relatively to the speed by LOG, not GPS.

When the slip is negative, there is nothing about favourable current, only wind or some unknown for me circumstances may affect. Sometimes negative slip is the source of incorrectly provided or calculated by maker figures, such propeller dimensions, pitch, etc.

1 nautical mile is equal to 1852 meters not 1800 m as indicated in the article

I have worked at sea for 43 years, and last 24 years as chief engineer, so very well verse about calculation at end of bunkering. Some suppliers use the term weight in vacuum, as in normal condition air give bouncy according to bunker calculation programs formulated by different supplier this weight in vacuum will be .0011% more than in normal condition. can say 11 kg/ton more in vacuum.

@Mueen: This is great. Thank you for this insightful comment. ??

Is this true?

Using consisted recordings of TSE at every noon report the developed power is simply calculated by subtracting daily readings, then using the Main Engine flow meters calculate fuel consumption per hour.

With these two values applied to the formula above SFOC is calculated?

I’m an electeical engineer. How could this help me? And why?

1NM= 1,852 meters not 1,800 meters